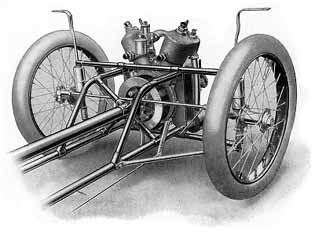

The Morgan Runabout was originally designed in 1909, and the machine as at present manufactured is the outcome of fifteen years' experience of one type of vehicle. We have never deviated from our original intention of manufacturing the most simple, reliable, and cheap running motor that it is possible to produce.

| Telephone 106. | Telegrams: "Morgan Motors." |

Valves. These should be examined frequently. The exhaust valves will require to be ground in more often than the inlet. Those in an air cooled engine should be attended to every 1,000 miles; in the water cooled engine the valves will run three times the distance. After the engine has run a very considerable mileage the inlet valve guides should be renewed, as if these are a loose fit on the valve stems a slow running will be impossible. Care should be taken that there is always a space of .003 inches between the end of the valve stem and the tappet. In new engines the exhaust valve sometimes sticks in its guide: this can generally be cured by squirting paraffin through the spring.

Exhaust Lifter. This is fitted to secure easy starting. It should be adjusted so that when the hand lever is pulled right up the exhaust valves are lifted about one-sixteenth of an inch. We do not advise the use of this lifter except for starting.

2

Cylinders. After running about 3,000 miles it is advisable to remove both cylinders in order to clean away carbon deposit from the cylinders and the top of the pistons. The piston rings should at the same time be examined. They should work quite freely in the grooves. If they do not they should be removed and cleaned. To remove the cylinders it is not necessary to take the engine out of the frame. In the case of the J.A.P. Engine it is important to see that the valve caps are always screwed up tightly, and with the M.A.G. great care must be taken in refitting the inlet valve. The parts must be absolutely clean before the four small nuts which hold the valve caps in place are screwed down. The running of many M.A.G. Engines is quite spoilt by lack of care in the fitting of the induction pipe and inlet valve cover.

Main Bearings. The engine bearings should last a very long time. We have known engines run over 10,000 miles without the need of re-bushing. When this is required we advise that the engine should be sent to the makers, in any ease the job should be done by an expert. Fitting new bearings throughout in a motor-cycle type engine is a comparatively inexpensive job (this is one of the advantages of this type of engine), but must be done properly.

The latest type J.A.P. engine has ball and roller bearings which are practically everlasting.

The engine should be driven carefully at first, and for the first 300 or 400 miles oil should be given very freely; afterwards one pump full for every 5 miles, or with a drip feed about 20 drops per minute will suffice - though when using low gear on long hills more should be given. If blue smoke issues from the exhaust when the car is running this shews that too much oil is being given. A good plan when starting for a run is to give the engine enough oil to make it smoke, then cut the supply down to normal.

3

Ignition is by magneto, which is fitted in front of the engine and is controlled by a lever on the steering wheel. In driving the ignition should be, left as fully advanced as possible. If, however, the engine knocks the ignition, should be retarded. When starting the ignition should be retarded very slightly.

The small platinum screw in the contact breaker is the only part which requires adjustment, and this very rarely. In timing the ignition, the spark in the fully retarded position of the ignition lever should take place when the piston is at the top of its stroke.

Plugs. It is most important that good plugs should be used; much overheating, especially in air cooled engines, is caused through unsuitable sparking plugs.

Carburetter. We fit the "B & B", "Amac" or " Binks" Carburetters with double lever controls. Booklets dealing with the adjustments of these Carburetters can be obtained on application. In driving open the throttle as little as possible and move the air lever into a position which is found to give the greatest power. For ordinary running a small jet should be fitted, for speed work and hill climbing larger jets are required. Very great care should be taken that the inlet pipe joints are absolutely air tight. It is advisable to wrap the union nuts tightly with insulation tape.

Petrol Filter. A small petrol filter is fitted under the petrol tap; this should be dismantled and cleaned out every 1,000 miles. The petrol tap need not be turned off unless the car is being left for a considerable time, as if the carburetter is in working order no leakage should occur.

4

Starting the Engine. Open the throttle a very little, shut the air and advance the spark to nearly the fully advanced position. In cold weather a little petrol should be injected into the cylinders through the compression taps. When starting from cold the carburetter should always be flooded. The starting handle should be turned rapidly and the exhaust lifter dropped whilst the handle is being turned.

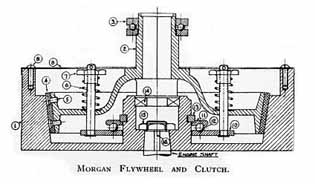

Clutch. The Clutch is fabric to metal and is enclosed in the fly wheel. Pressure is maintained by four small springs, which are easily adjusted by turning the hexagon nuts in front of them. If the clutch slips and does not take up, the drive quickly these nuts should be tightened.

If the clutch is fierce engine oil should be applied to the fabric. This can best be done with a syringe or oil-can through the hole drilled in the flywheel, the clutch being held out while the oil is poured in. The care and adjustment of the clutch is very important. It is quite safe to allow the clutch to slip when driving in traffic and when the motor is picking up. In fact the clutch should always be slipped when the car is running very slowly on top speed, to prevent the jerking of the engine doing harm to the transmission. But if the clutch is allowed to slip continuously from imperfect adjustment the fabric will be burnt away in a short time. With proper care the clutch fabric should last many thousand miles.

The thrust bearing inside clutch should be oiled occasionally. When the clutch is oiled a certain amount of oil finds its way to this bearing, otherwise an oil gun can be used through the openings of the brass clutch. It is important that the outside thrust bearing should be oiled every 200 miles.

5

The life of the chains, back tyre, and all parts of tile transmission depends on the proper use and condition of the clutch, so that great care should be taken that it is kept in thoroughly good order.

Parts of Clutch.

| l. Flywheel 3. Outside Thrust Bearing 5. Rivets or Screws 7. Adjusting Nuts 9. Cover Screws 11. Thrust Ring (round) 13. Split Ring 15. Flywheel Nut | 2.Brass Clutch 4. Fabric 6. Clutch Springs 8. Dust Cover 10. Thrust Ring (square) 12. Balls 14. Ball Race 16. Engine Shaft |

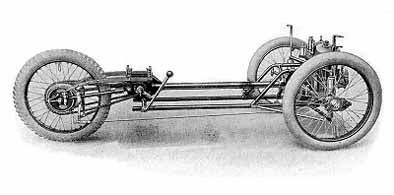

Gears. There are no gears on the Morgan such as used on most other cars. The gear box is situated under the back seat and contains a pair of bevel wheels. As these are very strong and run on annular bearings they require no attention beyond a regular supply of thick grease (good grease only must be used, inferior grease frequently contains water which will ruin the ball

6

bearings in a few months); this can be admitted by removing the small cover from the top of the gear box. When the car is new, it will use a considerable amount of grease, as a certain quantity will run into the two-inch propeller shaft tube. The dog clutches and change speed forks on each side of the box should, be oiled frequently.

Chains. From the gear box two chains transmit the power to the back wheel, giving high and low gear respectively. Our standard gears are 4½ to 1 and 8 to 1 or 5¼ to 1 and 11 to 1 for very hilly districts. (We can supply smaller or larger sprockets, to give other combinations, of gears.) After the machine has been in use for some time the chains will have stretched and will require adjustment. To adjust the chains, slacken the axle nuts and screw up the small brass adjustment nuts. (See also next section.) The high gear chain will stretch sooner than the low gear. On our latest models both chains are the same length, and can be reversed from high to low gear; this should be done every 1,000 miles. It is important that the chains are not allowed to become too loose, as there is danger of them riding on the sprocket teeth and breaking.

The life of the chains depends on, the attention given to them. They should be oiled regularly (the easiest way to oil the chains is to lift the cushion back and oil as the machine is being moved a little). Occasionally they may be taken off with advantage, cleaned and dipped into hot chain grease. As soon as much sign of wear appears, we advise new chains, as a badly worn chain is troublesome and throws a great strain on the sprockets. In fitting the chains it is very important to see that the chain nut is on the outside.

Brakes. Two brakes are fitted, one each side of the back wheel. These are easily adjusted by altering the positions of the brake clips. The brakes are lined with fabric and can easily be removed. It is important to remember that when the chains are adjusted the brake should be moved along the back fork.

7

Wheels. To remove the back wheel the pins holding each brake to the back fork clips must be removed, the axle nuts slackened, and the chain adjusters removed; the back wheel can now be taken out without undoing the chains, if the machine is fitted with our latest pattern back fork ends. The wheel should be jacked up 6 inches from the ground. This can be done by lifting the machine on to a petrol tin, which will support it underneath the gear box. The back wheel bearings require no adjustment. The front wheel bearings are the ordinary cup and cone type, and it is important that they should be adjusted when they become loose. The front wheels and the back wheel should be lubricated with grease. The front wheels are balanced to ensure good steering.

700 x 80 car rims are used, and tyres up to 700 x 85 can be fitted. From considerable experience we cannot at present recommend balloon tyres. We can, however, fit 810 x 90 rims and tyres at a small extra charge. These tyres are nearly as large as the balloon, but considerably stronger, and give a much greater mileage with no fear of punctures.

Tyres. We have found the "Stepney" and the "Kempshall" tyres most suitable, but any good rubber non-skid can be, used. On no account must a steel-studded tyre be used on the back wheel.

We have found from long experience that low tyre pressures are an advantage. We recommend a pressure of 25 to 30 lbs. in the front tyres, and 30 to 40 Ibs. in the back, according to the weight carried. It is advisable to replace the back tyre with a new one when the tread gets thin, the old tyre can then be used on one of the front wheels. With reasonable driving 5,000 miles at least should be got out of the back cover.

8

Chassis. All the frame tubes should occasionally be well cleaned and painted to prevent rust. The long exhaust pipes should also be scraped out on the inside, the silencers removed and the small holes cleaned out. These holes should not be enlarged as this weakens the frame. It is very important to see that the front axle tie rod is kept quite tight, also the four bolts which hold the engine in place.

Back Forks. The back forks rotate on a pin bearing which is in two halves bolted together with a long ½inch bolt. It is important to see that the castilated nut on the end of this bolt is kept tight. If after considerable use the bearings wear it is best to drill out the back forks and fit bushes. We can, however, supply over-sized tubes to, save the trouble of bushing.

9

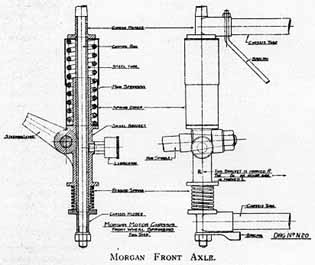

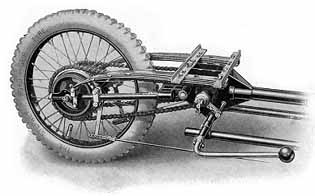

Springs. The front wheels are supported on spiral springs and slide vertically up and down. The stub or sliding axles should be renewed after about 6,000 miles, and must always be kept well greased. The back springs are of ordinary car type and should be greased between the leaves with graphite grease occasionally. If leather covers are used the greasing would not have to be done so often. We can supply these to order.

Steering. The steering is direct. The front wheels have a castor action which makes them self-centring, causing a slight drag on sharp curves. If the car tends to drag to one side the wheels are out of track (this can be altered by the adjustable steering rod), or one tyre is inflated to a higher pressure than the other. If the steering is bad and the front wheels wobble, the cause is probably that front frame tubes have been bent in an accident. They should be renewed or straightened very carefully.

Body Work. The Body can be completely removed from the chassis by removing two nuts behind the seat and taking off the front clips. The front mudguard bolts, oil, petrol and water pipes, also the steering arm at the end of the steering pillar, must be removed. It is very important to see that the body is securely fixed to the chassis, as any looseness causes vibration and much damage to the body work. The mudguard stays must be kept tight, otherwise they may break and the mudguards split. Th e appearance of the car depends almost entirely on the care that is taken with the body work. It should be housed in a dry motor house and regularly cleaned; a large soft sponge should be used finishing off with a chamois leather. A small bottle of black japan should be kept and used on black parts which are scratched to prevent rust; if any part of the body cracks or rattles it should be attended to immediately.

When the machine is not being used the hood should always be raised, this will give the material a longer life.

10

Fuel and 0il. We consider it pays to use the best quality petrol; benzol mixture, if of good quality, is very good, especially for air cooled engines, and a greater mileage to the gallon can be done on it than petrol. With regard to oil we recommend no particular brand, as we consider any of the best makes of air and water cooled oil quite satisfactory. It is fatal to use a cheap oil. With regard to grease for the gear box we find that "Vacuum" heavy transmission grease is the most suitable. For, the back hub we use Price's Bermoline.

To Change Gears. The clutch pedal should be pressed slightly while the gear lever is being moved. The gear lever should be moved as quickly as possible. Do not press on the clutch pedal except when using the clutch, as pressure on this pedal causes much wear on the clutch thrust bearing.

Cornering and Running. Although the car has been proved to be perfectly stable it is not wise to take corners too rapidly, as this in any case throws a great strain upon the tyres. The car is capable of very high speed, but it is not advisable to run the engine at full power for long distances until it has been well run in (say 500 miles). The most economical speed to run the car is from 20 to 30 miles an hour, but average speeds of well over 30 miles an hour can be obtained if required. It should be remembered that, as with all cars, the quicker the speed the greater the wear.

Remember that it is better to use too much lubricating oil than too little; and that it is most important to see that all nuts and bolts are kept tight, and that all working parts are clean and well oiled.

Much damage will be caused through neglect in attending to oiling and adjustment, and although the machine may run, it will not give the owner real satisfaction unless proper attention is given.

10

Competitions. We shall always be pleased to advise and help Morgan owners with regard to competition work. To be successful in reliability trials, it is necessary to see that everything is in A1 order, especially tyres and chains, also that you have a gear fitted, low enough to enable you to climb the steepest hill with ease.

Repairs. The machine should be occasionally overhauled. It is very simple and all adjustments and repairs are easily made, but in case of extensive repairs and overhauling it will be found cheaper and more satisfactory to send the machine to our works, or to one of our official repairers. We have a special department for repairs and customers can rely that the work will be done in our shops expeditiously and economically. The cost of even extensive repairs is very small compared with the cost of repairing motor cars, but an inexperienced workman may make the job far more expensive than is necessary. We can bring the oldest Morgan up to date, re-paint and upholster, and shall always be pleased to give a quotation for the work required.

Oil and Grease

| Every 100 miles | Sliding Axle Cups

Dog Clutches Chains Clutch Thrust Outside |

| Every 500 miles | Grease in Gear Box

Steering Joints Front Hubs Brake Rods |

| Every 1,000 miles | Spring Leaves

Back Hub Oil and Reverse Chains Clutch Fabric and Inside Clutch Thrust |

12

SPARE PARTS

The parts illustrated and described in the accompanying list are suitable, with a few exceptions, for all models of our make. Parts not now fitted but which are still obtainable are shown at the end of the list. Customers are, however, strongly advised to bring their machines up-to-date as, far as possible as renewals become necessary. The extra cost is negligible compared with the additional strength and longer life of the latest type fittings.

Several thousands of our machines are now in use and there is consequently a large demand on our spares department. Customers will, therefore, greatly assist by observing the following points and by so doing will ensure prompt delivery of parts :-

1. The car number should invariably be given when ordering. (This is to be found on the engine timing cover, near magneto bevel drive.)

2. Remittances to cover cost of goods and carriage should in all cases be sent with order. This obviates the necessity of sending a pro forma invoice, which is done when remittance is not enclosed. Customers holding deposit accounts should mark their orders clearly "DEPOSIT A/C".

3. All parts sent to us as patterns should be clearly labelled with the sender's name and address. Failure to do this results in unnecessary delay for which we are in no way responsible, but for which we are frequently blamed. Cheques or postal orders should not be enclosed with patterns and a separate letter of advice should be sent. Patterns are not returned unless asked for at the time of ordering. We accept no responsibility afterwards.

14

SPARE PARTS -continued.

4. Cheques and postal orders should be made payable to the firm and crossed. Treasury notes should in all cases be registered.

5. When remitting by telegraphic money order a separate telegram of advice should be sent. Unless this is done orders are likely to remain without attention as regulations do not admit of the sender's name being divulged on telegraphic money orders.

REPAIRS.

Machines or parts sent to us for repairs should be consigned "carriage paid" and should be clearly labelled with the sender's name and address. Instructions should be sent separately whether in estimate is required before the work is put in hand.

15